Home » Products » 3-Piece Can Production Line » 30CPM Automatic Tinplate Pail and Bucket Production Line

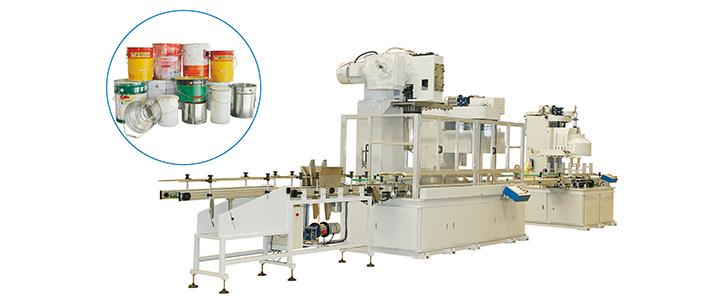

30CPM Automatic Tinplate Pail and Bucket Production Line

Features

After years' marketing experience, Jorson’s 30CPM automatic tinplate pail and bucket production line has been improved to be more simple and functional. The pail body is flanged twice and it can meet five to seven layers’ seaming requirements. So is the newly improved seamer. Clutch installed on the top of seamer, and overhead cam are all cancelled, making the whole line more simple and competitive.

Production Procedure

Vertical delivery of cans → Expanding → Pre-curling & Pre-flanging → Curling & Flanging → Beading → Can’s U-turning → Bottom seaming → Can body discharging → Connect with following procedures

Technical Parameters

| Output | 30CPM |

| Can height | 270-480mm |

| Can diameter | Φ220-300mm(need to shift molds) |

| Air pressure | Not lower than 0.6Mpa |

| Connection height | 1000±20mm |

| Overall weight | Approx. 12T(Not include ear welder) |

| Dimension(L×W×H) | 8500×1750×3100mm |

| Voltage | Three-phase four-wire 380 V(or customized) |

| Overall ower | Approx. 25KW |

Inquiry Form