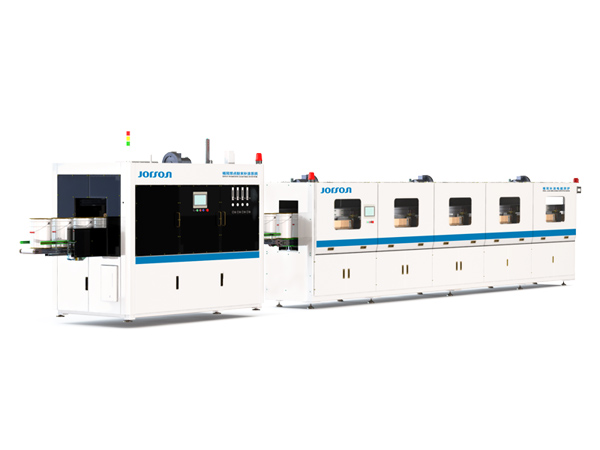

Spot Powder Coating & Curing System for Pail Lug

Inquiry

During production of pails and drums, handles are often required to be welded on the body or lid, where the internal coating will be damaged by the welding process. The damaged coating is traditionally repaired by manual or liquid spray coating, which is not suitable for foods and water-based paints and will lead to environmental pollution.

JORSON has developed a new technology for welded spot coating repair. This industry-leading powder coating technology allows powder to be sprayed precisely on the spots without contaminating other areas. The spot powder coating & curing system for pail lug is equipped with induction heating devices to dry the powder quickly. The powder is 100% recycled to achieve minimal material waste and environmental pollution. The powder coating is BPA-free and 2-3 times thicker than the liquid coating.

JORSON spot powder coating & curing system for pail lug contributes to decreasing more than 50% energy consumption and its fully automatic design will help to save 5-6 labor cost, which results in a significant reduction in the manufacturing cost of body and lid of pails/drums.

Advantages

- Labor saving

- Better protection

- No lacquer dropping

- No solvent pollution

- Best solution for water-based paint

- Only available in JORSON

Technical Parameters

Spot Powder Coating Machine

| Model | SPC50 | SPC50S | SPC50 PRO |

| Speed | 45cans/min | 50-60can/min | 45can/min |

| Coating Area Dia. | 42mm | 16-19mm | 42mm |

| Height | 220-420mm | 152-242mm | 200-500mm |

| Can Size | 284mm | 156-210mm | 245-330mm |

| Power | 16kW | 16kW | 16kW |

| Power Supply | 380v, 3 phases | 380V, 3 phases | 380V, 3 phases |

| Air Supply | 6 bar, 1000l/min | 6 bar, 1000l/min | 6 bar, 1000l/min |

Linear Oven

| Model | LOV50 | LOV50 PRO |

| Speed | 45can/min | 45-65can/min |

| Heating Type | Induction | Induction |

| Can Size | 284mm | 160-330mm |

| Height | 220-420mm | 140-500mm |

| Power | 20kW | 20kW |

| Power Supply | 380v, 3 phases | 380V, 3 phases |

| Number of Heating Head | 5pcs | 5pcs |