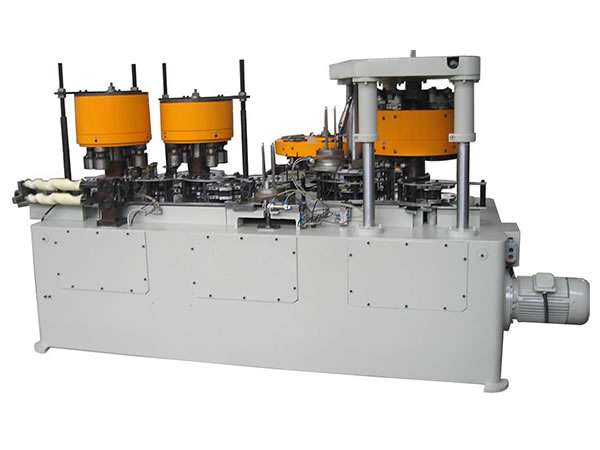

Combination Machine

The combination machine is used for necking, flanging, beading and seaming and vertically delivering cans. This combined machine is great for small metal cans, and uses a PLC controller from Mitsubishi in the electrical system.

Our combination machine can operate at low speeds when there is no metal can, and with its intelligent protection system, it can automatically shut down when metal can accumulate or it detects cans with no tops or bottoms.

The main motor on this metal can making machinery features stepless frequency control, which offers simple operation and easy changeovers.

Technical Parameters

| Name | Necking, Flanging, Beading and Seaming Three-Station Combination Machine |

| Item No. | |

| Production Rate | 80-300 cans/minute |

| Suitable Diameter of Can | ¢ 52- ¢99mm |

| Suitable Height of Can | H40-H124mm |

| Total Power | 7.5KW |

| Weight | 7,000Kg |

| Dimension | 2,500×1,300×1,300mm |

Inquiry Form