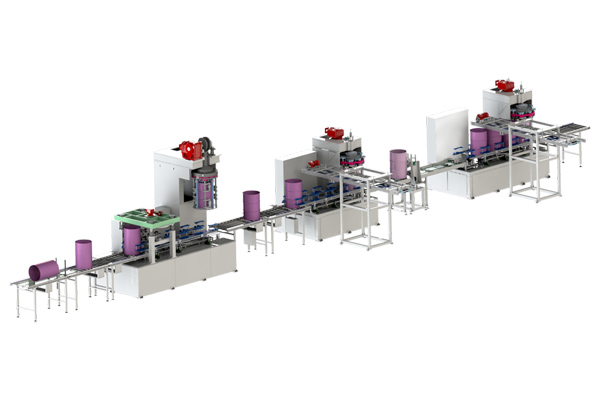

Automatic Steel Drum Manufacturing Line

The automatic steel drum manufacturing equipment is designed for the production of drum bodies with dual pre-coating and lamination. It completes beading and ripple forming in a single operation. The beading molds are automatically adjustable, and the ripple pattern can be selected as either W-shape or V-shape, depending on the drum design. The seaming process requires no coolant oil and does not involve rotating the drum body. The steel drum manufacturing equipment is fully automatic, offering flexible and efficient operation.

Technical Parameters

| Power | 270kW |

| Speed | 10-12 Drum/min |

| Drum Diameter | ⌀560mm-571mm |

| Drum Height | 910mm-930mm |

| Material Thickness | 0.6mm-1.2mm |

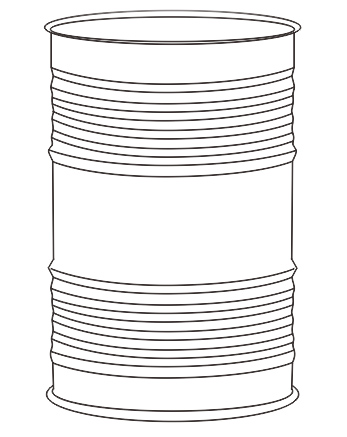

Manufacturing Process of Closed-Top Steel Drum

Inquiry Form