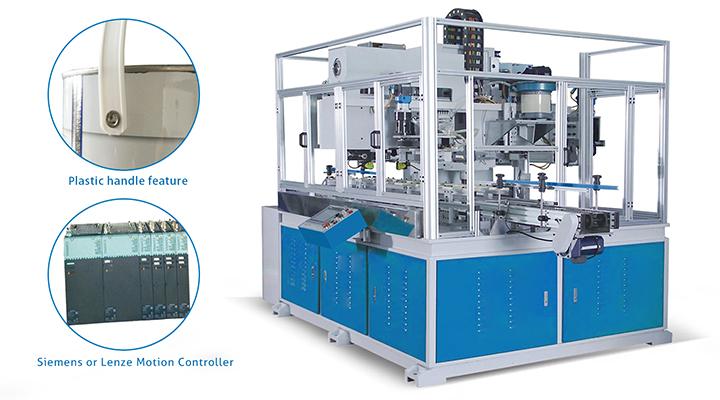

Tinplate Can Plastic Handle Forming and Ear Welding Machine

Plastic handle forming welding machine combines plastic handle punching, pail ear punching and ear welding together, carving a reputation as pioneers in plastic handle production field. Meanwhile, rivet-like ear and plastic strip, components for pail handles, are punched and welded directly in this machine, which leads to decreased material cost and labor cost. Besides, the machine introduces cams for conveying and transmission system, as well as electric cylinder feeding system and Siemens motion control system to make it run more accurately, flexibly, smoothly with high speed.

Technical Parameters| Applicable cans | Tinplate round can |

| Output | 60CPM |

| Production range | Φ155-180mm |

| Applicable height | 155-300mm |

| Distance between the bottle neck and the center of ear | 33-40mm (Adjustable) |

| Thickness of can body | 0.23-0.30mm |

| Thickness of rivets | ≥0.32 |

| Transformer secondary current | Approx. 5000A |

| Applicable air pressure | ≥0.6Mpa |

| Weight | Approx. 4.2T |

| Connecting height | 1000 ± 20mm |

| Dimension(L*W*H) | 3800*2700*2400mm |

| Overall power | 70KW |

Video

Inquiry Form

English

English Русский

Русский العربية

العربية Español

Español Español

Español