Stretch Hood Machines

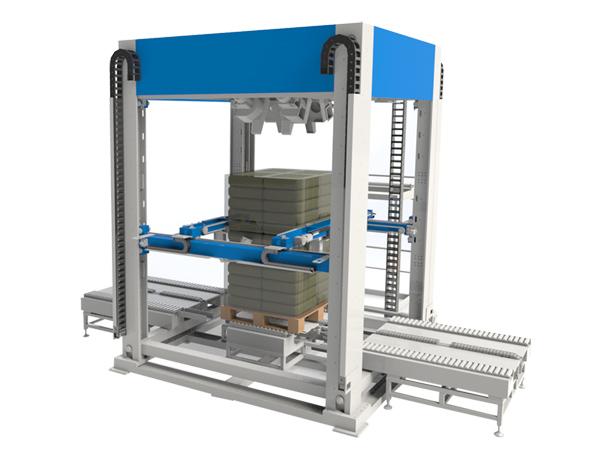

The stretch hood machine is designed to package goods using stretch film. During operation, as the goods enter the machine’s working area, it calculates the required film length based on the stacking height and pallet dimensions. Through its stretching, sealing, cutting, and hooding mechanisms, the film is applied from top to bottom. Leveraging the film’s elasticity and plasticity, the machine achieves a tight, five-sided wrap around the goods. The resulting package offers excellent water and moisture resistance, puncture protection, strong holding force, and stable stacking, while maintaining clear visibility of the contents. This technology is widely used in industries such as chemicals, building materials, home appliances, and animal feed.

- Tear resistance: Stretch film has excellent protection against environmental impacts and interference, ensuring that packaged goods are not exposed to moisture or scratches due to damaged packaging.

- Clamping system: Stretch film has good plasticity. After hooding, the stacked goods remain stable, preventing tipping or collapse during long-distance transportation.

Vertical Stretch Hood Machine (Fixed Length-to-Width Ratio)

The D-VL vertical stretch hood machine is designed for applications where pallet sizes remain consistent or vary in fixed proportions, and where higher packaging speeds are required. Custom design options are available to ensure the equipment matches the height of the goods. For demanding applications, an optional hydraulic system can be added to deliver greater stretching force. Key features include a height-adjustable film-stretching mechanism for improved film-change efficiency, an identification and sensor system for comprehensive product protection, and safety devices to prevent collisions or load displacement during operation.

Suitable for industries such as can manufacturing, chemicals, building materials, automotive parts, home appliances, and food, where pallet sizes are uniform or change proportionally.

| Stretch circumference | 4800 mm |

| Pallet load height | 600~2600 mm (includes pallets) |

| Film thickness | 80~120μm |

| Ambient temperature | ≤40℃ |

| Coil diameter | ⌀600~1000mm |

| Coil width | 2100mm |

| Reel diameter | ⌀76mm |

| Coil weight | <600kg |

| Voltage | 380V |

| Air consumption | 300L/min |

Stretch Hood Machines (Vertical Variable Length Width Ratio)

The B-VM stretch hood machine integrates advanced technologies to meet the needs of customers handling a wide variety of products. It can easily adapt to items of different lengths, widths, and heights, even when they are processed on the same production line, and can be configured to accommodate changes in pallet size. A multi-roll film system reduces film consumption, while a height-adjustable film-stretching mechanism enhances film-change efficiency. An integrated identification and sensor system ensures comprehensive protection of goods, and safety devices prevent collisions or load displacement during operation.

Suitable for industries such as can manufacturing, chemicals, building materials, automotive parts, home appliances, and food, where pallet sizes and shapes are diverse.

| Stretch circumference | 5000mm |

| Pallet load height | 600~1900 mm (includes pallets) |

| Film thickness | 100~150μm |

| Ambient temperature | ≤40 ℃ |

| Coil diameter | ⌀600~1000mm |

| Coil width | 2100mm |

| Reel diameter | ⌀76 mm |

| Coil weight | <800kg |

| Voltage | 380V |

| Air consumption | 260L/min |

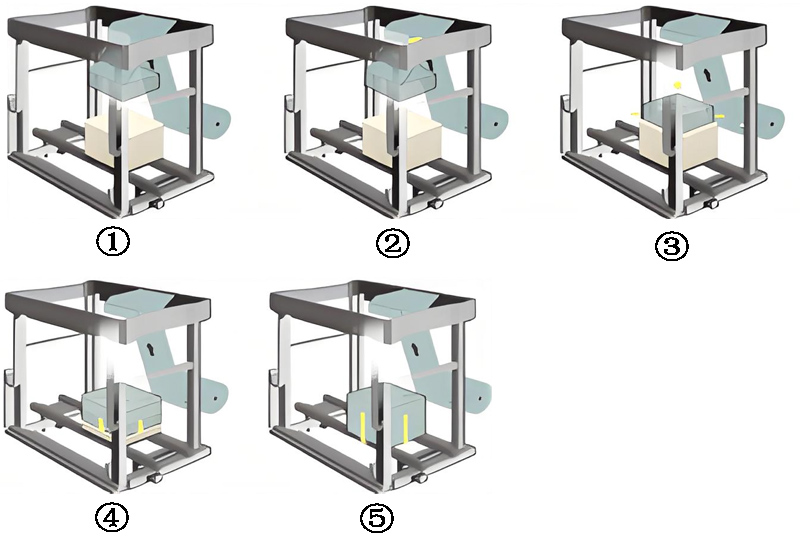

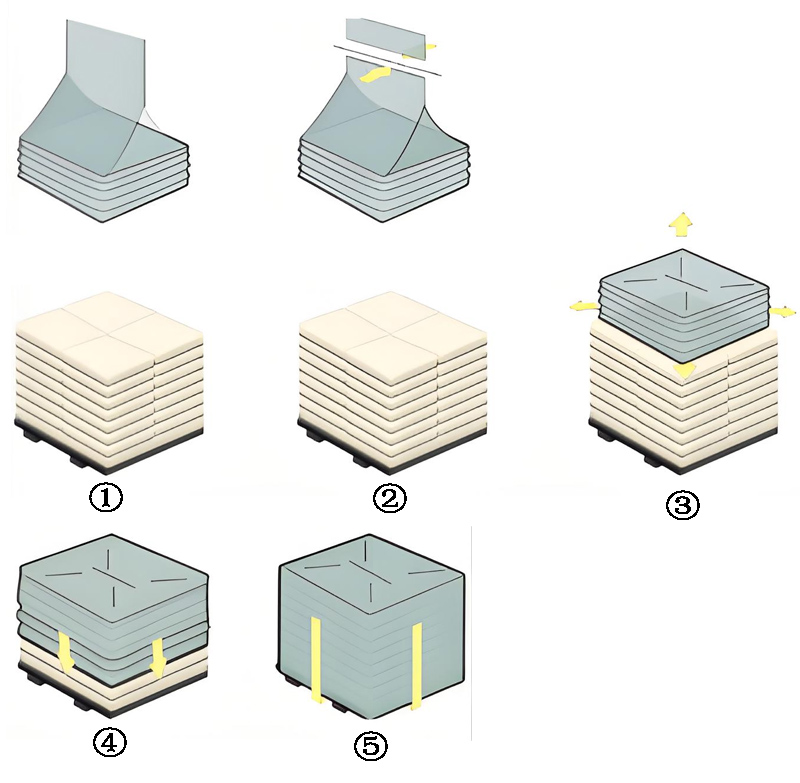

- Goods in place

- Film cutting and sealing

- Hood formed ready to be stretched

- Hooding

- Completed stretch hooding