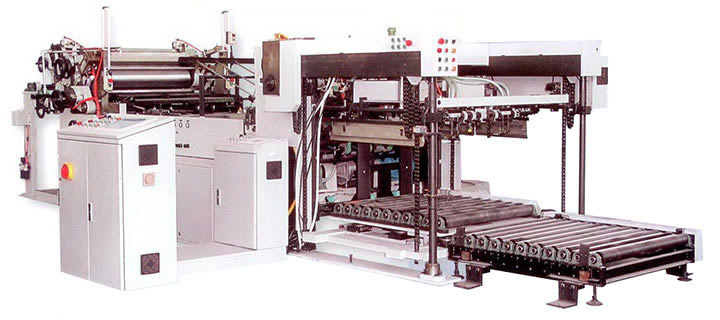

Coating Machine

RYTB450B Coating Machine Features

1. The coating roller and the pressure motor are driven separately by two motors.

2. Assembly and disassembly of the rubber roller: the end face tooth clutch and the bolt clamping are both controlled by the air cylinder.

3. Phase adjustment of the coating system: the circumferential direction of the rubber roller can be adjusted while the machine is running, at a range of ±11 mm.

4. The pressure between each roller on our coating machine can be adjusted on both the operating side and the engine side either at the same time or individually with the use of a hand wheel.

5. The side regulation system's fixed side regulation consists of several small diameter rollers, and the buffer surface is installed with two buffer cylinders.

6. Our coating machine has a singly located pusher, which is adjusted on the operating side by an electromagnetic clutch.

7. There are three front regulations on the positioning rollers of our coating equipment, and the clutch systems are all manipulated by cylinders.

8. Our coating machine has a dual scarper system that is coordinated with a lubrication device, which ensures there are no residual materials on the pressure roller. The assembly and disassembly of the scrapers is completed on the operating side, and the pressure is adjusted using the cylinder's pressure.

9. The coating with blanks and the full coating are controlled by the tension clutch.

10. The pusher and side regulation's format adjustments are automatically controlled by the conventional servo motor.

11. The feeder's synchronous regulation is achieved by using the electronic mechanism while the machine is running.

12. The side and rear boards of the feeder are adjusted by the motor drive.

13. Our metal can coater comes with four cleaning rollers, and its feed system is driven by an electric motor.

14. The four directions of the stockpile can also correct automatically.

| Max. Sheet Size | 1,145×950mm |

| Min. Sheet Size | 680×473mm |

| Conveyor Line Height | 916mm |

| Rubber Cloth Size | 324-339mm(fully covered) 329±0.5mm(with space) |

| Rubber Roller Length | 1,145mm |

| Coating Speed | 6,000 sheets/hour |

| Coating Roller | φ220×1,145 |

| Pressure Roller | φ220×1,145 |

| Weight | Approx.8,500Kg |

English

English Русский

Русский العربية

العربية Español

Español Español

Español