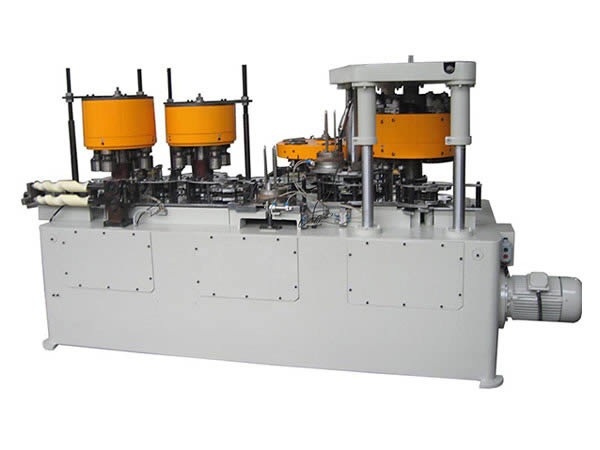

Necking Machine

Our necking machine vertically delivers metal cans and is used for aerosol necking, flanging, and both bottom and top seaming. Our electrical system is controlled using a Mitsubishi PLC control system. It is auxiliary metal can making equipment which is easy to operate, and its mold changeover is convenient.

This aerosol can necking machine’s main motor features a stepless frequency control and is equipped with a series of intelligent protective systems. It can automatically switch to a low speed operation when there are no metal cans to be processed, and this necking machine will automatically stop when output has accumulated or it detects uncovered metal aerosol cans.

Technical Parameters

| Item No. | |

| Function | Necking, flanging, bottom seaming, top seaming |

| Production Rate | 20-120 cans/minute |

| Applicable diameter of can | ¢ 52- ¢65mm |

| Applicable height of can | H110-H320mm |

| Total Power | 7.5Kw |

| Weight | 8,000Kg |

| Dimension | 2,000×1,400×1,230mm |